Case IH owners are now able to make better-informed farm management decisions based on both real-time and historic data generated by their machines, with the launch of AFS Connect, a subscription-based telemetry package which integrates proven elements of Case IH Advanced Farming Systems technology to link fields, machines and data.

The launch follows the preview of the cloud-based MyCaseIH.com web platform, AFS telematics portal and AFS Connect Mobile iOS/Android app at SIMA 2019 earlier this year. In combination, these elements automatically display and store machine and field data, and allow users to monitor and manage it both from an office computer and remotely from a smartphone or tablet. With permission, Case IH dealers can also monitor machines, helping them ensure they are running at peak performance and remotely identify any issues.

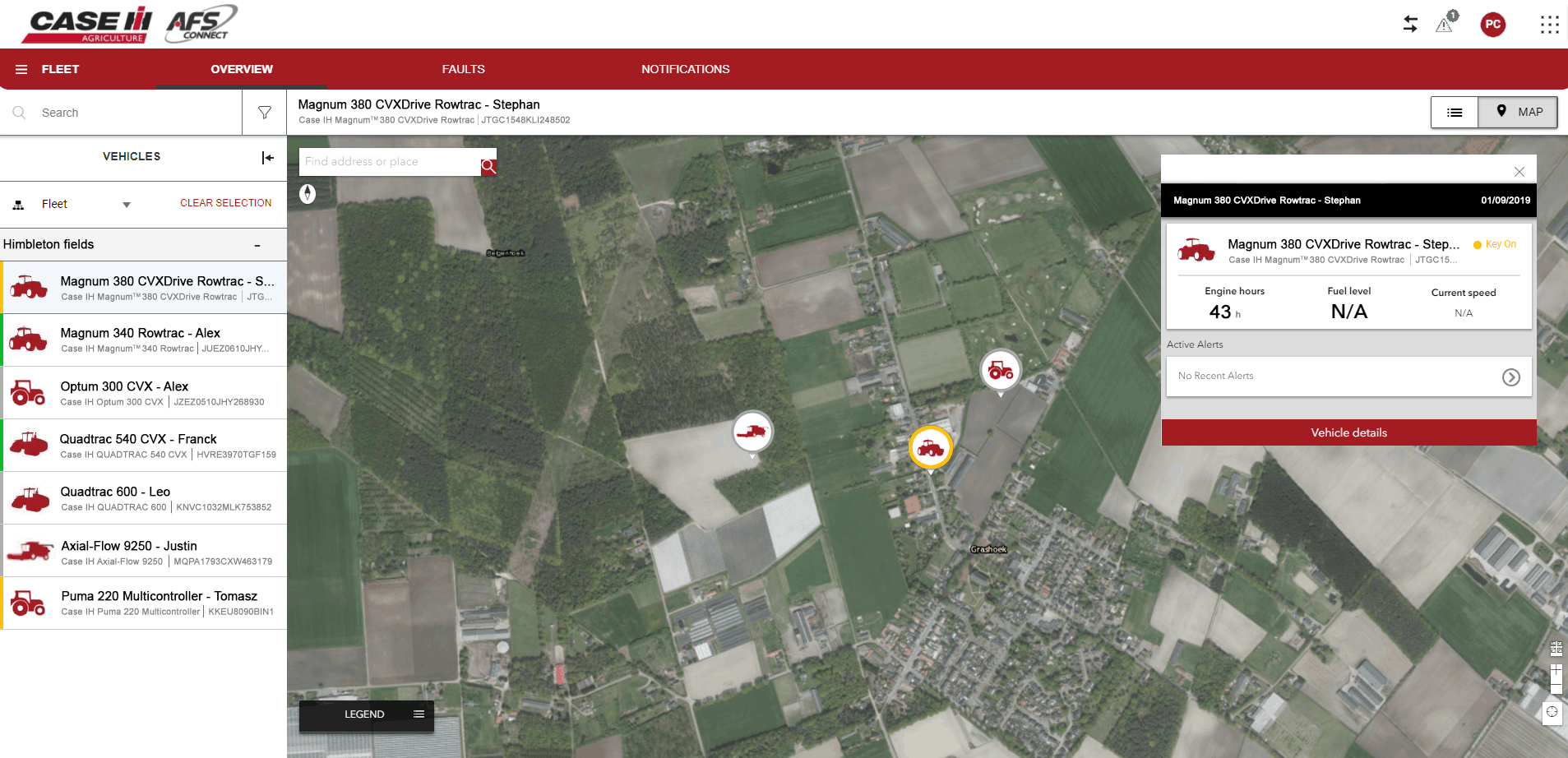

AFS Connect has two data management divisions — fleet management, and data management — that users can monitor and manipulate from any desktop, tablet or mobile device using the mycaseih website and app. The first element is a core part of the standard subscription package, while the second and third are options. The only requirements for use of the system are an AFS Connect subscription which provides an unlock code, and a modem. In the cab, AFS Connect works with the latest AFS 1200 operating terminal.

Remote monitoring and recording

Precision farming technology users wishing to download from their machines recorded data such as yield maps, or upload work plans such as variable rate seed and fertiliser maps, have traditionally had to do so by linking a farm PC/desktop computer with the operating terminal in the cab of their tractor or other self-propelled machine by using USB memory sticks to transport the data between the two. Potential downsides of this include the need to physically hand over the USB when machine and manager may be some distance apart, plus the possibility the USB may be the incorrect one for the task, or may become damaged or corrupted. With Case IH AFS Connect, these inconveniences and potential risks are eliminated, with farm owners and managers able to not only receive and analyse – instantly or post-completion – machine performance data, but also to plan field operations from an office PC or smart device before work even begins. Plans can then be sent remotely to the tractor and its operator.

“These plans can include data such as A-B lines and prescription maps for variable seed rates, for example,” explains Maxime Rocaboy of Case IH.

“Once work in the field is underway, AFS Connect also allows the viewing of live maps showing machine location and work completed. This ensures machines are in the right place and are working correctly, and assures owners and managers they do not leave a designated area through operator error or theft. It also reduces downtime by, for example, enabling remote fuel level monitoring to time fuel deliveries to the field, minimising downtime.”

Fleet Management

Via the Fleet Management portal, both owners/managers and operators can easily monitor machine performance via the AFS 1200 in-cab terminal or the web portal or app. Data such as machine hours, temperatures, engine speeds and services due are constantly recorded and updated, and like all other data transfer this is automatic and seamless. Customisable phone text alerts can be set if the tractor operates outside a preset value, such as a certain engine rpm or operating temperature. Identification of any issues or problems allows farm managers and owners to proactively plan and execute maintenance.

“AFS Connect brings instant recording and monitoring to the farmer’s fingertips, with no need to use an easy-to-damage or lose USB drive or memory stick to transfer data between tractor terminal and a desktop computer or laptop,” says Maxime Rocaboy.

“With data immediately gathered in the cloud and immediately available for analysis, wherever owners and managers may be they can be assured, via access to their PC or smart device, that all is well with the machine and that an operation is progressing as it should.

“On the other hand, they can also be assured that if an issue becomes apparent they can quickly be notified of it – and, with permission, so can their dealer. That means it is likely to be identified much more quickly, and therefore addressed more promptly, while with dealer monitoring, notification of an issue – and, where possible, remote diagnosis of the problem – mean the dealer can attend to the machine prepared with any parts required, reducing downtime and cost.”

Kirk Wesley, Case IH Advanced Farming Systems marketing manager for North America, where the system has been commercially available for the past year, underlines the fact that any data gathered – even that shared with those who the tractor owner has chosen to give permission, such as the Case IH dealer or a third party such as the farm’s agronomy company – remains the property of the machine owner.

“We do nothing with that data – only store it and make it available to the owner and anyone else the machine owner gives permission to,” he says.

“Users have the possibility to trial the potential value of third-party data access for a 30-day period after delivery of their machine before opting-in to data sharing. If they choose not to do so, then their data will no longer be monitored or be accessible to anyone but them.

“We have designed AFS Connect to be particularly easy to work with, and full support is available from Case IH dealers. Users can also find guidance, where required, from an extensive YouTube library we have developed, with short, easy-to-follow videos that explain how to do things such as generate reports of machine status and fuel usage.”

Following its first year during 2018-19 on the North American market, where it has proven particularly popular, the public European launch of the technology will take place at Agritechnica 2019, from 10-16 November. It will be available to buyers of any Case IH tractors and combines that can be fitted with AFS technology, including Maxxum, Puma, Optum, Magnum, Steiger and Quadtrac tractors, and Axial-Flow combines.